A note on "cheap" alternatives

Holden memcals are programmed from the factory with very specific configurations. They are programmed for parameters such as: engine size, intake size, exhaust flow rate, fuel injector size and type, sensor configuration, transmission controls, dashboard data and everything that the computer controls to make it all run correctly together. Each memcal matches it’s ECU counterpart with a 4 letter designation (eg. CJKM).

We have seen many ‘eBay’ type units sold as performance chips but when read, they only have a stock Holden file.

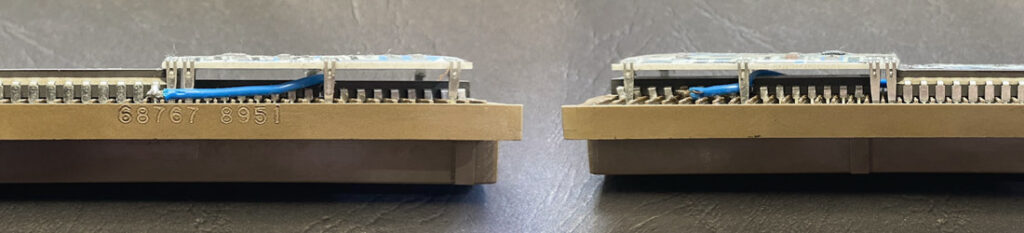

Look out for bridge links soldered between the EEPROM and knock board, this usually indicates a V6 memcal being used as a HSV unit. This “hack” will allow the injectors to function as per the V8 memcal however the knock boards are not like for like. It may work partially but not correctly.